In today’s competitive restaurant and hospitality industries, operational efficiency and customer satisfaction go hand in hand with revenue growth. PathSpot, a leader in hygiene technology, empowers businesses to protect their brand while driving measurable financial returns. By minimizing waste, improving employee retention, and fostering a safe environment for customers and staff, PathSpot becomes an essential investment for long-term profitability. Here’s how:

1.Reducing Waste and Spoilage

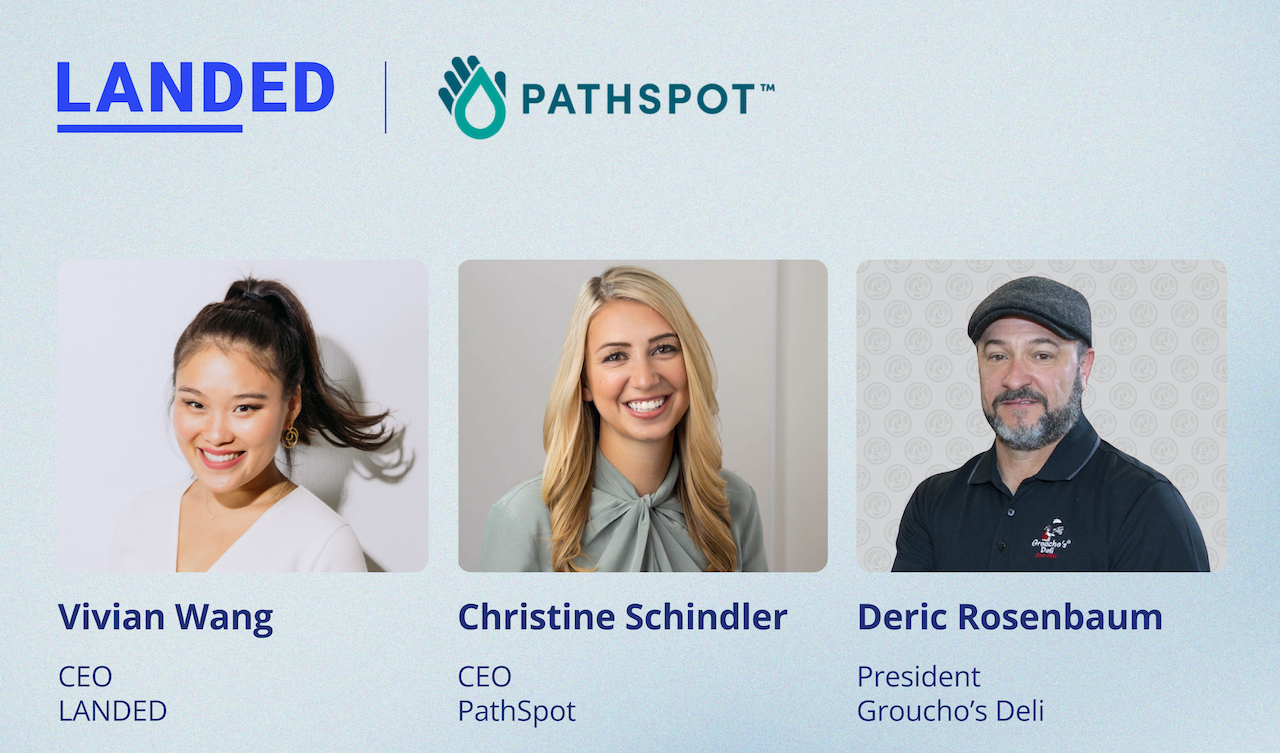

Food waste is a silent revenue killer for many businesses. Spoilage due to improper handling, contamination, or inconsistent storage practices not only leads to financial loss but also undermines food safety. PathSpot’s technology mitigates this risk by ensuring employees maintain the highest hygiene standards, preventing cross-contamination and keeping products safe for use. Businesses that reduce waste and maintain safe food practices are better positioned to improve their bottom line by lowering operating costs. Watch Deric Rosenbaum (President of Groucho’s Deli) speak on why PathSpot is a necessity for your business here!

2. Boosting Employee Retention

High employee turnover disrupts operations and increases recruitment and training costs. A culture of safety and care can significantly impact employee satisfaction and retention. When employees feel confident that their workplace prioritizes their health and safety, they are more likely to remain loyal. PathSpot helps cultivate this culture by empowering employees with technology that reinforces best practices and promotes accountability. As highlighted in our recent blog post and webinar, creating a safety-first environment fosters long-term employee commitment, reducing costly turnover.

3. Creating a Safe and Happy Environment for All

A clean, hygienic space isn’t just about compliance—it’s about customer trust and loyalty. Consumers are increasingly aware of the importance of health and safety in dining experiences. PathSpot’s real-time data and insights ensure that restaurants and hospitality businesses can proactively address hygiene issues before they become problems. A safe environment translates to happy customers, glowing reviews, and repeat business, all contributing to increased revenue and a stronger reputation.

The Bottom Line: Safety and Profitability Go Hand in Hand

Investing in PathSpot isn’t just about maintaining compliance—it’s about building a foundation for sustainable revenue growth. From reducing unnecessary waste to enhancing employee satisfaction and delivering exceptional customer experiences, PathSpot empowers businesses to operate efficiently while maximizing profitability.

Ready to see how PathSpot can elevate your operations and increase your revenue? Contact us today to learn more!

See our last blogpost to dive deeper into how a clean and safe workspace can improve employee retention: