In today’s food service industry, maintaining cleanliness goes beyond simply meeting regulations—it’s about creating a safe and healthy environment for both customers and employees while safeguarding your business’s reputation. With the proper hygiene and safety practices in place, you can prevent foodborne illnesses, protect public health, and build trust with your customers. Clean hands serve as the first line of defense in ensuring a safer, healthier food-handling environment, helping your business thrive while keeping everyone safe. Learn more here

The Importance of Food Safety in Food Service

Food safety is the cornerstone of success for any business involved in food preparation, packaging, or service. By prioritizing proper hygiene practices, businesses not only protect the health of their customers but also build a reputation for trust and quality. While millions of people are affected by foodborne illnesses each year, many of these cases are preventable, and businesses have the opportunity to lead the way in creating safer dining experiences. Beyond avoiding fines or closures, maintaining top-notch food safety protocols empowers businesses to prevent cross-contamination, stop the spread of harmful bacteria, and ensure the well-being of everyone they serve.

The Need for Technology-Driven Solutions

In the age of digital transformation, relying solely on manual processes for hygiene compliance can no longer meet the demands of a high-paced food service environment. Traditional handwashing signs and routine inspections may remind workers to wash their hands, but they cannot guarantee compliance or effectiveness.

Food service businesses need real-time, actionable data that ensures hygiene standards are being met consistently. Tech-driven solutions offer the ability to monitor and verify cleanliness, providing peace of mind that hand hygiene is upheld to the highest standards at all times. HandScanner Data info here

Clean Hands: The Cornerstone of Hygiene

Clean hands are vital to preventing foodborne illnesses, and thanks to advances in digital technology, ensuring proper hand hygiene has never been easier. While handwashing has always been essential, studies show that compliance can sometimes fall short. However, with innovative solutions now available, businesses can actively monitor and verify that employees are washing their hands effectively and consistently. This reduces the risk of pathogens like E. coli and Salmonella and strengthens the overall food safety strategy. By embracing these tools, food service companies can take proactive steps to create a safer, healthier dining environment. This is where technology can play a pivotal role in ensuring food safety. Food Safety Tech Info here

Beyond Handwashing: A Holistic Approach to Food Safety

While clean hands are critical, food safety extends far beyond hand hygiene. Ensuring the protection of the food supply requires monitoring multiple control points, including temperature regulation food labeling and expiration management. For instance, refrigeration units must maintain specific temperatures to prevent the growth of harmful bacteria. Similarly, proper labeling and expiration tracking are essential for preventing spoiled or expired products from reaching consumers.

The food service industry’s focus on these protocols and hygiene creates a safer environment for workers and customers. By digitizing safety practices and reducing reliance on manual, paper-based processes, companies can take a holistic approach to food safety, covering everything from hand hygiene to food storage.

The ROI of Food Safety Technology

By investing in safety technology, businesses not only improve hygiene but also optimize their workforce, cut costs, and avoid the significant financial toll of foodborne illness outbreaks. With digital solutions, companies can better allocate labor, increase efficiency, and enhance their bottom line—making it a win-win for both safety and profitability. ROI of Food Safety

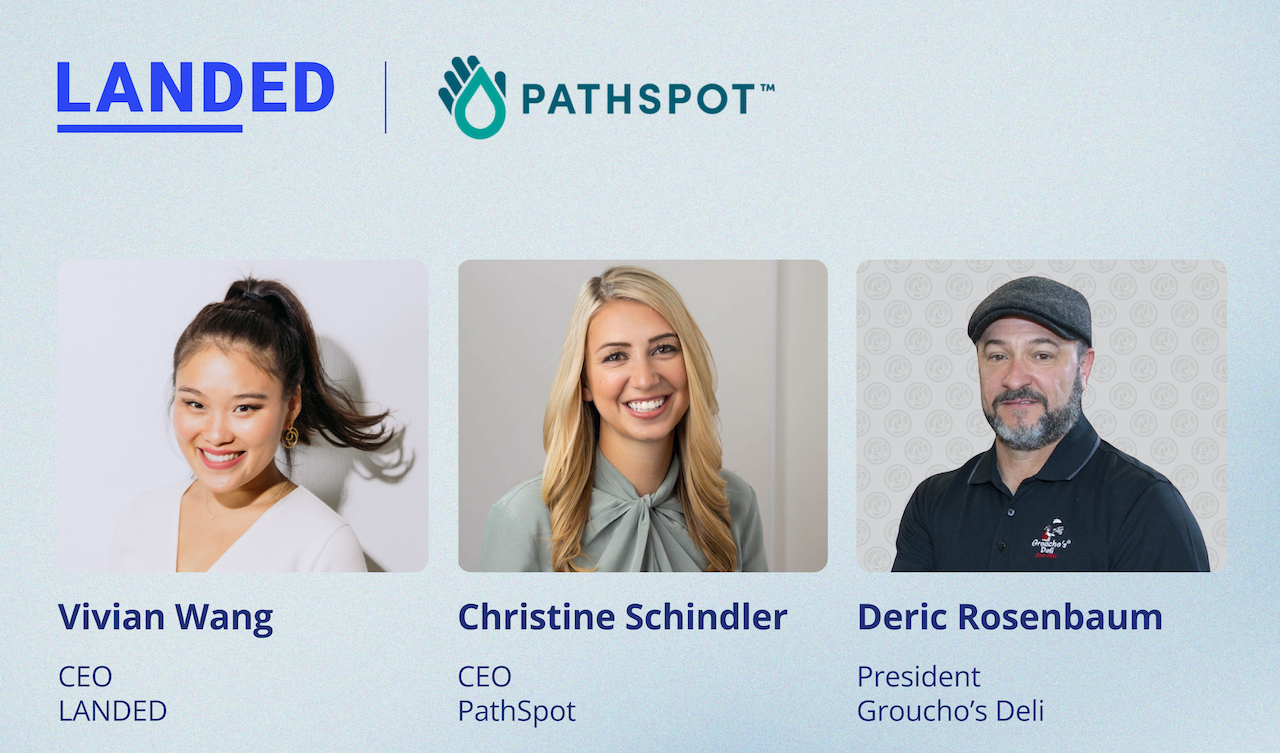

Introducing PathSpot: A Game-Changing Tech Solution

PathSpot’s innovative food safety technologies created a low-cost, durable solution to combat foodborne illness outbreaks. Christine Schindler, PathSpot’s CEO & Co-Founder, sat down with John Jannarone, editor-in-chief of IPO Edge, at the NASDAQ Market Site to discuss how PathSpot is revolutionizing food safety technology to combat the growing issue of foodborne illnesses. Full Interview Link Here

Hand hygiene is one of the most significant contributors to illness in the food service industry. PathSpot’s flagship product the HandScanner provides BOH staff with a way to check for invisible contaminants on their hands in less than two seconds. This revolutionary technology replaces outdated methods like the “employees must wash hands” signs, offering real-time, actionable insights that help prevent foodborne illnesses. By empowering food service workers with immediate feedback to ensure cleanliness, the HandScanner drastically reduces the risk of contamination and illness in restaurants, hotels, grocery stores, and other food-handling environments.

PathSpot recognized the complexity of food safety and expanded its services to include a comprehensive SafetySuite that provides for temperature monitoring, expiration management, labeling, and digitized safety task checklists.

These digital solutions replace cumbersome, manual processes, allowing businesses to easily track critical control points, reduce risks, and streamline operations—all while ensuring they stay compliant with safety standards. This holistic approach ensures that food service businesses can meet the highest standards of the safety standards board—whether in restaurants, hospitality, or food manufacturing plants.

Partnerships and Global Expansion

PathSpot’s impact has been significant, partnering with major global brands such as Taco Bell, Marriott, and Target to enhance food safety protocols. These businesses have adopted PathSpot’s technology not only to ensure hygiene compliance but also to streamline safety processes, improve their bottom line and have happy customers.

As the food service industry continues to globalize, PathSpot is expanding with thousands of locations and hundreds of thousands of employees worldwide using its technology leading the way in transforming food safety practices on a global scale. By integrating data and identifying key risk factors, these organizations take proactive measures to prevent contamination, save time, and reduce operational costs. Tech Driving Real Change

Conclusion: The Future of Food Safety

Food safety is more than just a regulatory obligation—it’s an essential aspect of customer care and business success. Clean hands are the first step in preventing foodborne illnesses but must be part of a larger, comprehensive safety system. By adopting technology-driven solutions like PathSpot, food service companies can ensure they’re meeting the highest cleanliness and safety standards, protecting both their customers and their brand.

PathSpot’s cutting-edge technology is setting a new baseline for hygiene in the food service industry, helping businesses around the world reduce the risk of illness, streamline operations, and create safer environments for everyone involved. To learn more about how PathSpot’s HandScanner and SafetySuite can be the Clean Tech your Food Service Company Needs Book A Demo Today!